The aim of the project is to develop a new, bio-based, smart and fully recyclable composite material, obtained by a fast and low energy consumption out-of-autoclave process.

The matrix will be made by

Aeronautics and automotive industries are the main sectors of interest in FURHY-project.

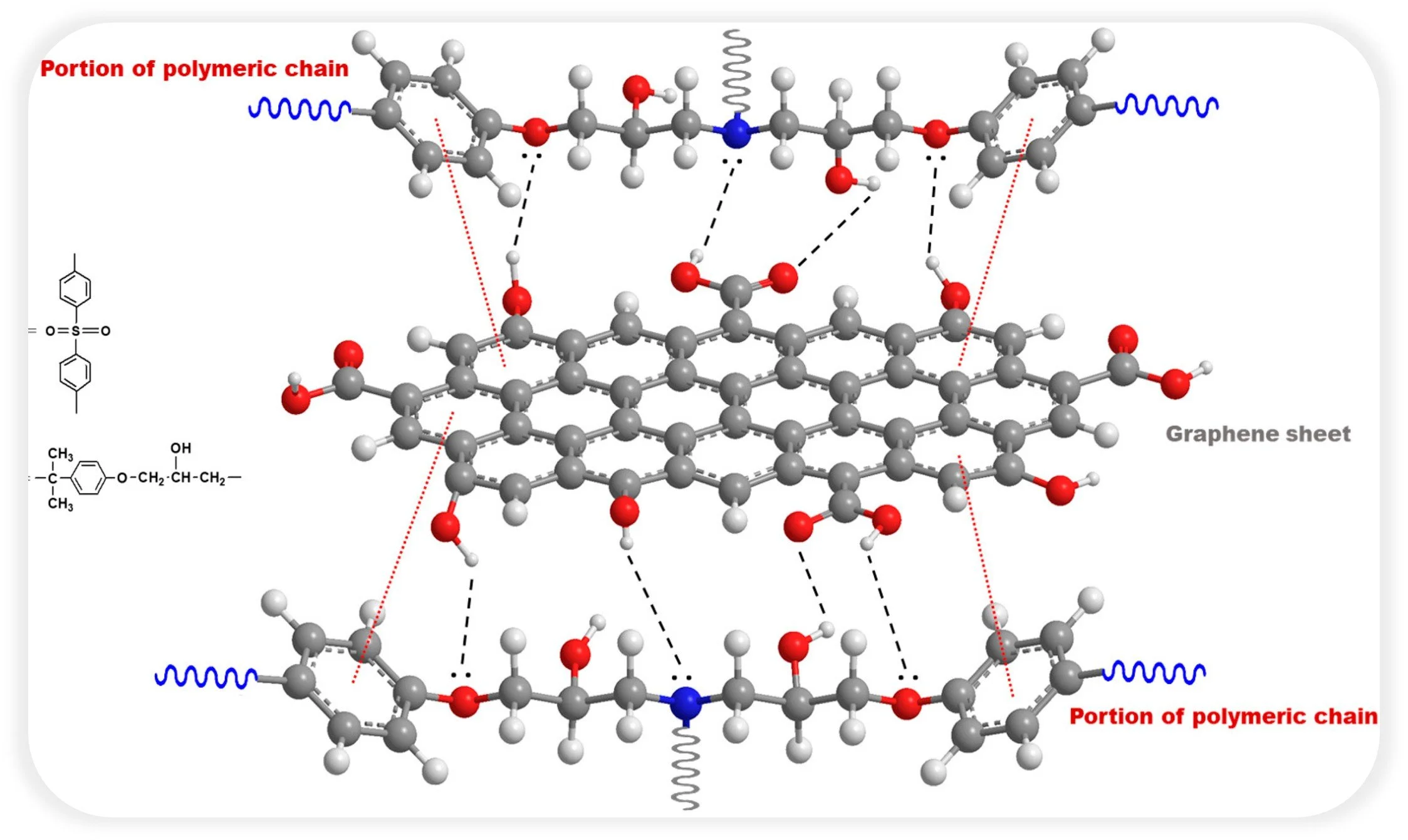

Development of a new bio-based epoxy resin formulation filled with expanded graphite (EG), which will play multiple roles in the enhancement of both the material and the manufacturing process, providing smart functions.

Development of a hybrid composite using hemp and recycled carbon fibers (rCFs), thus maximizing the environmental benefits with a life-cycle perspective.

The hybridisation will let to exploit the advantages offered by both fibres, minimizing the relevant drawbacks. The manufacturing process will consist in a low energy version of the prepreg compression moulding (PCM).

1

2

3

OBJECTIVES

Develop an optimized bio-based, fast curing, recyclable epoxy resin.

Design and develop a set of new composites to tailor functionality for a range of possible applications.

Design components for 2 aeronautic and 2 automotive applications, with the new materials.

Develop a new recycling technology suitable for the recovery of all the constituents of the composite structure.

Demonstrate the validity of the proposed business case.

Develop hybrid

reinforcing fibres textiles.

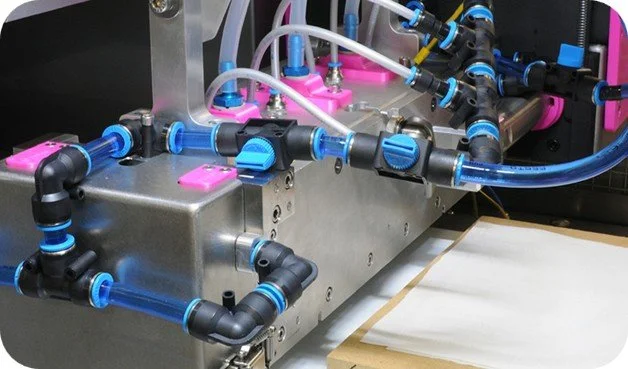

Develop an energy saving, high performance prepreg compression moulding (PCM).

7

4

5

6

WORK PACKAGES

-

WP1

Project Management

-

WP2

Development of epoxy resin formulation

-

WP3

Fiber coating and hybrid textile development

-

WP4

Prepregs and composites manufacturing processes development

-

WP5

Material characterisation and self-functions analysis

-

WP6

Development of hybrid laminates and component demonstrator design

-

WP7

Recyclability demonstration and sustainability evaluation

-

WP8

Dissemination, communication and exploitation

Reduced production cost of renewable lightweight materials, 25% lower cost than currently used materials

Lightweight products containing >50% sustainable, bio-based materials

Up to 30% lightweight potential through tailored functionality for a range of extreme environments

CO2 emission reduction (LCA) of at least 20%

Business models and circular value chains for bio-based lightweight components

Industrial leadership and increased autonomy in key strategic value chains with security in raw materials supply

IMPACT

KEY EXPLOITABLE RESULTS

KER 1 - PCM PROCESS MODIFIED WITH ELECTRO-CURING [TRL5]

[PROCESS] Innovative electro-curing method for a fast and low energy consumption prepreg compression molding.

KER 2 - INNOVATIVE FORMULATION OF BIO-BASED RECYCLABLE EPOXY RESIN [TRL5]

[PRODUCT | PROCESS] Depolymerizable biobased building blocks, as well as the synthesis, polymerization and depolymerization processes for them.

KER 3 - DESIGN OF N. 2 AEROSPACE COMPONENTS [TRL5]

[PRODUCT] Design and manufacturing of aerospace components with thermosetting made of recycled and carbon/hybrid fibers.

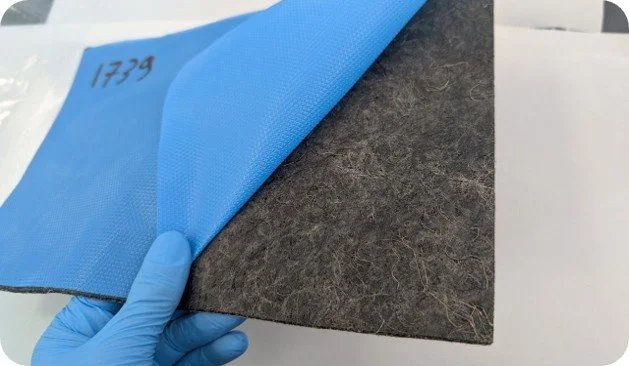

KER 4 - HYBRID HEMP/rCF NON-WOVEN DEVELOPMENT [TRL3]

[PRODUCT] Non-woven material that combines rCF with hemp which has significantly higher green credentials and offering a low carbon footprint.

KER 5 - LCA OF THE NOVEL MATERIAL

[KNOW-HOW] Knowledge acquired to be used in sustainability consultancy activities portfolio towards companies involved in all the stages of the bio composites supply chain.

KER 6 - DESIGN OF N. 2 AUTOMOTIVE COMPONENTS [TRL5]

[PRODUCT | PROCESS] Design of lighter, cheaper, and more sustainable automotive components using recyclable composites to replace traditional metals.

KER 7 - ADDITIVATION OF EXPANDED GRAPHITE FOR SMART FUNCTIONS [TRL3]

[PRODUCT | PROCESS] Development of a multifunctional materials through an energy-efficient process with the integration of expanded graphite into epoxy resin with smart properties suitable for SHM and de-icing applications in the transport sector.

KER 8 - DEVELOPMENT OF THE NOVEL ECO-SUSTAINABLE PREPREG [TRL3-4]

[PRODUCT | PROCESS] Development of a production process for prepregs using innovative non-woven fabrics made entirely of hemp or a blend of hemp and rCF.

KER 9 - PLASMA COATING DEVELOPMENT FOR HEMP FIBRES [TRL5]

[PROCESS] Plasma coating of hemp to improve the adhesion of hemp to composite resins.